- Leak Detector

- Vacuum Products

- Claw Pump

- Diaphragm Pumps

- Diffusion Pumps

- Dry Rotary Vane Pumps

- Dry Screw Pump

- Dry Scroll Pumps

- Ion Pumps

- Laboratory Vacuum Pumps

- Liquid Ring Vacuum Pump & Compressor

- Piston Vacuum Pump

- Roots Pumping Systems RPS Series

- Rotary Vane Pumps

- Spare Parts & Accessories

- Turbo Pumping Systems

- Turbo Pumps

- Vacuum Components

- Vacuum Measurement

- Vacuum System

- Furnace

- Digital Oscilloscopes

- Yokogawa

- Rigol

- Rigol DS70000 Series Digital Oscilloscope

- Rigol Digital Oscilloscope MSO8000 Series

- Rigol Digital Oscilloscope MSO/DS7000 Series

- Rigol Digital Oscilloscope DS6000 Series

- Rigol Digital Oscilloscope MSO5000 Series

- Rigol Digital Oscilloscope MSO/DS4000 Series

- Rigol Digital Oscilloscope MSO/DS2000 Series

- Rigol Digital Oscilloscope DS1000 Series

- GW Instek

- Saluki

- Siglent

- Data Acquisition

- DC Electronic Load

- DC Power Supply

- Digital Multimeters

- LCR Meter

- Signal Generator

- Network Analyzer

- Spectrum Analyzers

- Waveform Generators

- Test & Measurement

- Flow Meter

- Manometer

- Optical Test

- Power Electronics Training Systems

- Safety Tester

- Other Meters

- Accessories for Test & Measurement

- Cable & Antenna Analyzer

- Cable & Pipe Locators

- Clamp Meter

- Comprehensive Tester

- GPS / GNSS Simulators

- Insulation Tester

- Non-Contact Voltage Tester

- Power Analyzer & Power Meter

- Power Supply

- Thermal Imager & Thermometer

- Transformer

- Professional Cleaning Equipment

- Professional Power Tools

- Angle grinders & metalworking

- Benchtop Tools & Benches

- Carrying Case

- Cordless Tools

- 12 Volt System

- 18 Volt System

- 18V Tools

- 36 Volt System

- Charger

- Cordless Angle Grinder

- Cordless Drywall Screwdrivers

- Cordless Dust Extractors

- Cordless hand-held circular saws

- Cordless impact drills

- Cordless Impact Drivers/Wrenchers

- Cordless Jigsaw

- Cordless Multi-Cutter

- Cordless Orbital Sander

- Cordless Palm Router

- Cordless Planer

- Cordless Reciprocating Saw

- Cordless Rotary Hammer

- Cordless Rotary Tool

- Cordless Straight Grinder

- Cordless Worklights

- Measuring Technology

- Diamond Technology

- Drills & impact drills & screwdrivers

- Dust Extraction Systems

- Heat Guns & Glue Guns

- High-Pressure Washer

- Measuring Technology

- Rotary Hammers & Demolition hammers

- Routers

- Sanders & Planers

- Saws

- Stirrers

- Rental

- MRO

- Jonnesway

- RS Pro

- Beacons

- Cabinet Coolers

- Cable Clips & Clamps

- Cage Nuts

- Camlocks

- Chisels

- Coaxial Cable

- Code Locks

- Compression Springs

- Counters

- Cutters

- DIN Rail Power Supplies

- Door Bolts

- Door Catches

- Door Closers

- Door Latches

- Door Stops

- Drawer Handles & Cabinet Handles

- Electronic Sounders

- Energy Meters

- Fixed Installation DC-AC Power Inverters

- Hammers

- Hasp & Staples

- HDMI Cables

- Heater Pads

- Heating Elements

- Hex Keys

- Impact Sockets

- Industrial Hubs & Switches

- Jack Cable Assemblies

- Multicore Microphone & Instrument Cable

- Number & Letter Punch Sets

- Nut Drivers

- Pliers

- Punches

- Rack Cable Management

- Rack Panels

- Rackmount Cases

- Screw Extractors

- Screwdriver Bit Sets

- Screwdriver Bits

- Screwdriver Sets

- Screwdrivers

- Scribers

- Sensor Accessories

- Server Cabinet Accessories

- Server Rack Shelves

- Single Core Microphone Cable

- Socket Accessories

- Socket Sets

- Socket Wrenches

- Spanner Sets

- Spring Plungers & Indexing Plungers

- Tap & Die Wrenches

- Temperature Control Accessories

- Temperature Controllers

- Temperature Probes

- Temperature Transmitters

- Thermocouple & Extension Wire

- Thermocouples

- Thermostatic Switches

- Time Switches

- Timer Relays

- Torque Screwdrivers

- Torque Wrenches

- Torx Keys

- USB Cables

- USB Extension Cables

- VGA Cables

- Others

- TEMO

- Skinny Tools

- Algodue

- Greenwipes

Hexo Industries (M) Sdn Bhd

1-2-9, i-Avenue, Medan Kampung Relau 1, 11900 Bayan Lepas, Penang, Malaysia.

+6011-6528 1088

+604-611 1186

+6012-954 1088

+604-611 1186

+6012-954 1088

+6012-558 2052

+60129541088

Selangor Branch

Jalan Putra Bistari 2/5J, 47610 Subang Jaya, Selangor, Malaysia

Indonesia Branch

Jababeka Bizpark, Blok D/16, Jababeka Innovation Center, Pintu 6, Blok D/16, Cikarang, Bekasi, Jawa Barat 60292, Indonesia.

Singapore Branch

SpectrumSense Solutions

1 Scotts Road, #24-10 Shaw Centre, Singapore 228208.

Agilent TwisTorr 305-IC Turbo Pump with Integrated Controller

| Previous | 4 / 39 | Next |

Turbo Pumps

Features

Literature

Related Products

Support

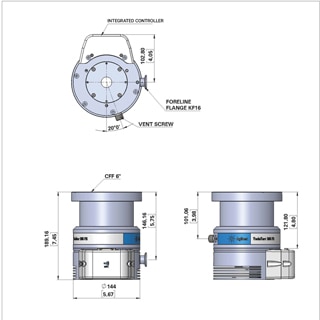

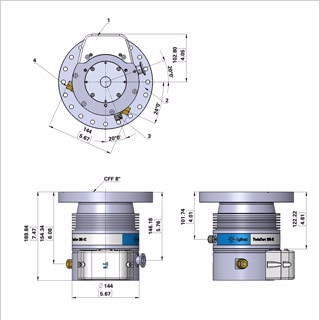

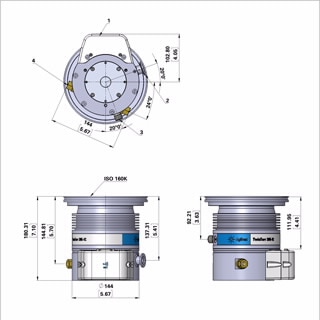

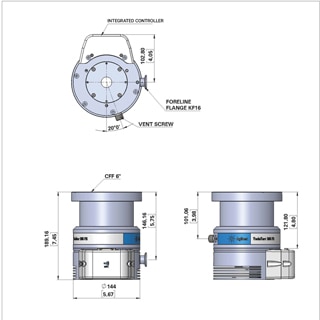

TwisTorr 305-IC CFF6 Turbo Pump Outline Drawing TwisTorr 305-IC ISO 100K Turbo Pump Outline Drawing

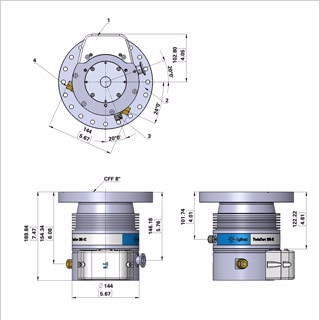

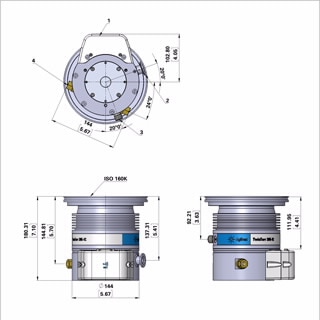

TwisTorr 305-IC CFF 8 Turbo Pump Outline Drawing TwisTorr 305-IC ISO 160K Turbo Pump Outline Drawing

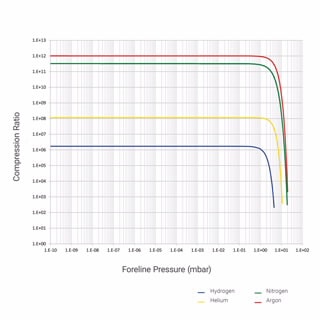

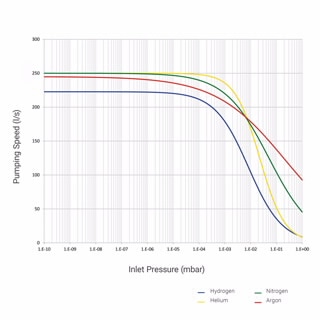

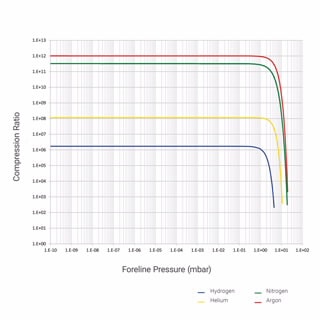

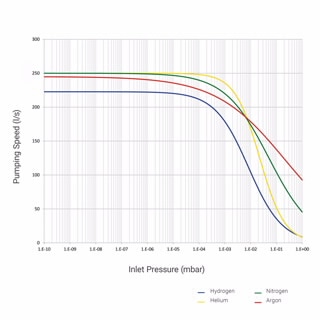

TwisTorr-305-IC-Compression-Ratio TwisTorr-305-IC-Pumping-Speed

TwisTorr 305-IC Turbo Pump with Integrated Controller

The TwisTorr 305-IC turbomolecular pump with integrated controller features a revolutionary design and smart connectivity through near-field communication (NFC).

This 300 L/s turbo pump communicates seamlessly with the Vacuum Link app.

Due to its compact form factor and small size, the TwisTorr 305-IC is ideal for use in any instrument and any industrial application requiring a high compression ratio and low vibration.

Order Infomations

| 9699344 | Vibration Isolator ISO 100 |

| 9699302 | Inlet Screen CFF 6” |

| X3500-68000 | Inlet screen ISO 100 |

| 9699347 | Metric Water Kit 4 x 6 mm |

| 9699304 | Inlet Screen CFF 8” |

| X3500-68001 | Inlet Screen ISO 160 |

| X3513-68000 | KF25 Foreline flange |

| X3514-68001 | TwisTorr 305-IC Fan/Vent Adapter kit |

| 9699345 | Vibration Isolator ISO 160 |

| 9699334 | Vibration Isolator CFF 6” |

| 9699337 | Water Cooling Kit for Turbopump |

| 9699232 | Purge valve 10 SCCM ¼ Swagelock - ¼ Swagelock |

| 9699239 | Purge valve 10 SCCM NW16KF - M12 |

| 9699241 | Purge valve 20 SCCM NW16KF – M12 |

| 9699240 | Purge valve 10 SCCM ¼ Swagelock - M12 |

| 9699242 | Purge valve 20 SCCM ¼ Swagelock - M12 |

| 9699236 | Purge valve 20 SCCM ¼ Swagelock - ¼ Swagelock |

| 9699335 | Vibration Isolator CFF 8” |

| X3500-68010 | Air cooling kit for TwisTorr 305-IC and onboard controller (Kit X3514-68001 is required for IC controller) |

| X3500-68011 | Air cooling kit for TwisTorr 305 remote controller |

| 9699834 | Vent Valve N.O. 1, 2 mm for TwisTorr 305-IC and onboard controller (Kit X3514-68001 is required) |

| X3513-64000 | TwisTorr 305-IC ISO100 air cooling, 485A |

| X3513-64001 | TwisTorr 305-IC CFF6, air cooling, 485A |

| X3513-64002 | TwisTorr 305-IC ISO160 air cooling, 485A |

| X3513-64003 | TwisTorr 305-IC CFF8, air cooling, 485A |

| X3513-64004 | TwisTorr 305-IC ISO100 wat cooling, 485A |

| X3513-64005 | TwisTorr 305-IC CFF6, wat cooling, 485A |

| X3513-64006 | TwisTorr 305-IC ISO160 wat cooling, 485A |

| X3513-64007 | TwisTorr 305-IC CFF8, wat cooling, 485A |

| X3513-64016 | TwisTorr 305-IC ISO100 air cooling, 485P |

| X3513-64017 | TwisTorr 305-IC CFF6, air cooling, 485P |

| X3513-64018 | TwisTorr 305-IC ISO160 air cooling, 485P |

| X3513-64019 | TwisTorr 305-IC CFF8, air cooling, 485P |

| X3513-64020 | TwisTorr 305-IC ISO100 wat cooling, 485P |

| X3513-64021 | TwisTorr 305-IC CFF6, wat cooling, 485P |

| X3513-64022 | TwisTorr 305-IC ISO160 wat cooling, 485P |

| X3513-64023 | TwisTorr 305-IC CFF8, wat cooling, 485P |

| X3513-64024 | TwisTorr 305-IC ISO100 air cooling, 232 |

| X3513-64025 | TwisTorr 305-IC CFF6, air cooling, 232 |

| X3513-64026 | TwisTorr 305-IC ISO160 air cooling, 232 |

| X3513-64027 | TwisTorr 305-IC CFF8, air cooling, 232 |

| X3513-64028 | TwisTorr 305-IC ISO100 wat cooling, 232 |

| X3513-64029 | TwisTorr 305-IC CFF6, wat cooling, 232 |

| X3513-64030 | TwisTorr 305-IC ISO160 wat cooling, 232 |

| X3513-64031 | TwisTorr 305-IC CFF8, wat cooling, 232 |

- New generation integrated control unit

- Low noise levels - 41 dB(A) at full speed

- High compression ratios for light gases

- Compact size

- Smart power management

- Oil-free solution

- Low-maintenance cost

- Multiple configurations available for various flange sizes and air/water cooling

- Full range of accessories

| Technical Specifications | ||||

| Pumping speed | ISO 100 K / CFF 6”/ ISO 160 K / CFF 8” | |||

|

N2 He H2 Ar |

250 L/s 255 L/s 220 L/s 250 L/s |

|||

| Max gas flow rate | ||||

| N2 | 250 SCCM | |||

| Compression ratio | ||||

|

N2 He H2 Ar |

> 1 x 1011 > 1 x 108 1.5 x 106 > 1 x 1011 |

|||

| Max foreline pressure tolerance N2 | 12 mbar | |||

| Base pressure with recommended forepump |

<1 x 10 -10 mbar (<1 x 10 -10 Torr) |

|||

| Inlet flange | ISO 100 K, CFF 6”, ISO 160 K, CFF 8” | |||

| Foreline flange | KF16 NW (KF25 - optional) | |||

| Rotational speed | 60000 rpm (1010 Hz driving frequency) | |||

| Start-up time | < 3 minutes (longer when soft start is used) | |||

| Recommended forepump |

Dry pumps: IDP-3 (no gas flow), IDP-7, IDP-10, Mechanical: DS102, DS302 |

|||

| Operating position | Any | |||

| Oper. ambient temperature | +5 °C to +35 °C | |||

| Bakeout temperature | Max 80 °C at inlet flange | |||

| Lubricant | Permanent lubrication | |||

| Cooling requirements | ||||

| Air cooling |

Natural convection (only with no gas load) Forced air (5- 35 °C ambient temperature) |

|||

| Water cooling |

Minimum flow: 50 l/h (0.22 GPM) Temperature: +15 °C to +30 °C Max pressure: 5 bar (75 psi) |

|||

|

Noise pressure level (at 1m at full speed) |

41 dB(A) | |||

| Storage temp. | -40°C to +70°C | |||

|

Weight kg (lbs) TwisTorr 305-IC |

ISO 100 K 5,74 kg (12,6) CFF 6’’ 8,06 kg (17,7) ISO 160 K 6,18 kg (13,6) CFF 8’’ 10.33 kg (22.7) |

|||

| Compliance with: |

EN 61010-1 EN 61326-1 EN 1012-2 EN 12100 EN 50581 Machinery Directive 2006/42/EC Electromagnetic Compatibility Directive 2014/30/EU Directive 2011/65/EU |

|||

| Power supply (24 Vdc): | ||||

|

Input voltage Max input power Stand-by power Max operating power |

24 Vdc 200 W 10 W 150 W with water or air cooling |

|||

| Protection fuse | 8 A | |||

| USB communication | as per USB 1.1 | |||

Literature

- Brochures

-

- Data Sheets

-

- Software

-

Related Products

Support

- FAQs

-

- User Manuals

-

TwisTorr 305-IC CFF6 Turbo Pump Outline Drawing TwisTorr 305-IC ISO 100K Turbo Pump Outline Drawing

TwisTorr 305-IC CFF 8 Turbo Pump Outline Drawing TwisTorr 305-IC ISO 160K Turbo Pump Outline Drawing

TwisTorr-305-IC-Compression-Ratio TwisTorr-305-IC-Pumping-Speed