- Leak Detector

- Vacuum Products

- Claw Pump

- Diaphragm Pumps

- Diffusion Pumps

- Dry Rotary Vane Pumps

- Dry Screw Pump

- Dry Scroll Pumps

- Ion Pumps

- Laboratory Vacuum Pumps

- Liquid Ring Vacuum Pump & Compressor

- Piston Vacuum Pump

- Roots Pumping Systems RPS Series

- Rotary Vane Pumps

- Spare Parts & Accessories

- Turbo Pumping Systems

- Turbo Pumps

- Vacuum Components

- Vacuum Measurement

- Vacuum System

- Furnace

- Digital Oscilloscopes

- Yokogawa

- Rigol

- Rigol Digital Oscilloscopes DS80000 Series

- Rigol Digital Oscilloscope DS70000 Series

- Rigol Digital Oscilloscope MSO8000 Series

- Rigol Digital Oscilloscope MSO/DS7000 Series

- Rigol Digital Oscilloscope DS6000 Series

- Rigol Digital Oscilloscope MSO5000 Series

- Rigol Digital Oscilloscope MSO/DS4000 Series

- Rigol Digital Oscilloscope MSO/DS2000 Series

- Rigol Digital Oscilloscope DS1000 Series

- Rigol Digital Oscilloscope MHO/DHO5000 Series

- Rigol Digital Oscilloscope MHO2000 Series

- Rigol Digital Oscilloscope MSO8000A Series

- GW Instek

- Saluki

- Siglent

- Others

- Data Acquisition

- DC Electronic Load

- DC Power Supply

- Digital Multimeters

- LCR Meter

- Signal Generator

- Network Analyzer

- Spectrum Analyzers

- Waveform Generators

- Test & Measurement

- Flow Meter

- Manometer

- Optical Test

- Power Electronics Training Systems

- Safety Tester

- Other Meters

- Accessories for Test & Measurement

- Cable & Antenna Analyzer

- Cable & Pipe Locators

- Clamp Meter

- Comprehensive Tester

- GPS / GNSS Simulators

- Insulation Tester

- Non-Contact Voltage Tester

- Power Analyzer & Power Meter

- Power Supply

- Thermal Imager & Thermometer

- Transformer

- Professional Cleaning Equipment

- Professional Power Tools

- Angle grinders & metalworking

- Benchtop Tools & Benches

- Carrying Case

- Cordless Tools

- 12 Volt System

- 18 Volt System

- 18V Tools

- 36 Volt System

- Charger

- Cordless Angle Grinder

- Cordless Drywall Screwdrivers

- Cordless Dust Extractors

- Cordless hand-held circular saws

- Cordless impact drills

- Cordless Impact Drivers/Wrenchers

- Cordless Jigsaw

- Cordless Multi-Cutter

- Cordless Orbital Sander

- Cordless Palm Router

- Cordless Planer

- Cordless Reciprocating Saw

- Cordless Rotary Hammer

- Cordless Rotary Tool

- Cordless Straight Grinder

- Cordless Worklights

- Measuring Technology

- Diamond Technology

- Drills & impact drills & screwdrivers

- Dust Extraction Systems

- Heat Guns & Glue Guns

- High-Pressure Washer

- Measuring Technology

- Rotary Hammers & Demolition hammers

- Routers

- Sanders & Planers

- Saws

- Stirrers

- Rental

- MRO

- Jonnesway

- RS Pro

- Beacons

- Cabinet Coolers

- Cable Clips & Clamps

- Cage Nuts

- Camlocks

- Chisels

- Coaxial Cable

- Code Locks

- Compression Springs

- Counters

- Cutters

- DIN Rail Power Supplies

- Door Bolts

- Door Catches

- Door Closers

- Door Latches

- Door Stops

- Drawer Handles & Cabinet Handles

- Electronic Sounders

- Energy Meters

- Fixed Installation DC-AC Power Inverters

- Hammers

- Hasp & Staples

- HDMI Cables

- Heater Pads

- Heating Elements

- Hex Keys

- Impact Sockets

- Industrial Hubs & Switches

- Jack Cable Assemblies

- Multicore Microphone & Instrument Cable

- Number & Letter Punch Sets

- Nut Drivers

- Pliers

- Punches

- Rack Cable Management

- Rack Panels

- Rackmount Cases

- Screw Extractors

- Screwdriver Bit Sets

- Screwdriver Bits

- Screwdriver Sets

- Screwdrivers

- Scribers

- Sensor Accessories

- Server Cabinet Accessories

- Server Rack Shelves

- Single Core Microphone Cable

- Socket Accessories

- Socket Sets

- Socket Wrenches

- Spanner Sets

- Spring Plungers & Indexing Plungers

- Tap & Die Wrenches

- Temperature Control Accessories

- Temperature Controllers

- Temperature Probes

- Temperature Transmitters

- Thermocouple & Extension Wire

- Thermocouples

- Thermostatic Switches

- Time Switches

- Timer Relays

- Torque Screwdrivers

- Torque Wrenches

- Torx Keys

- USB Cables

- USB Extension Cables

- VGA Cables

- Others

- TEMO

- Skinny Tools

- Algodue

- Greenwipes

Hexo Industries (M) Sdn Bhd

1-2-9, i-Avenue, Medan Kampung Relau 1, 11900 Bayan Lepas, Penang, Malaysia.

+604-611 1186

+6012-954 1088

Selangor Branch

Jalan Putra Bistari 2/5J, 47610 Subang Jaya, Selangor, Malaysia

Indonesia Branch

Jababeka Bizpark, Blok D/16, Jababeka Innovation Center, Pintu 6, Blok D/16, Cikarang, Bekasi, Jawa Barat 60292, Indonesia.

Singapore Branch

SpectrumSense Solutions

1 Scotts Road, #24-10 Shaw Centre, Singapore 228208.

EVP - Steam Ejector System

| Previous | 15 / 20 | Next |

Description: EVP steam ejector and air ejector with water-saving, steam conservation features, it’s widely used in edible oil,waste oil refining,fatty acid distillation, deodorization.

Product Info:

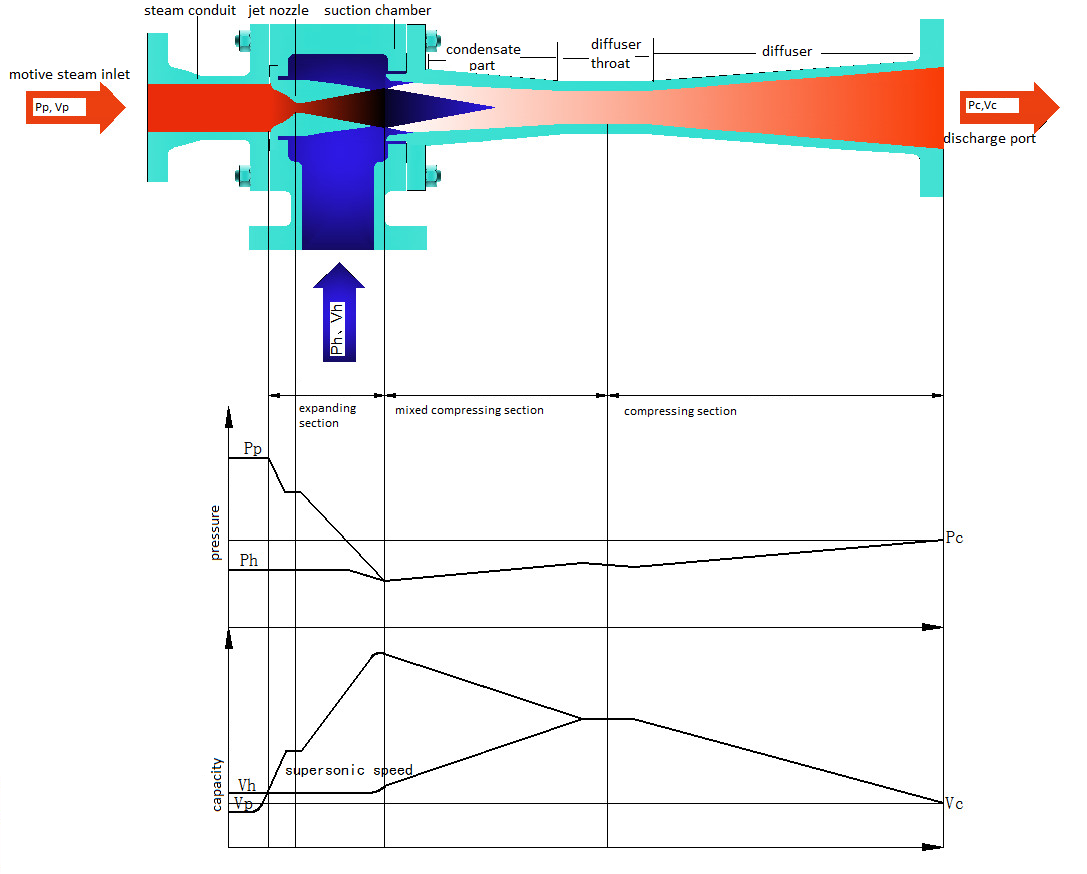

Steam ejector is type of vacuum obtain device with certain pressure. Motive steam passing through the jet nozzle£¬its pressure decreased and speed accelerated, the steam’s potential energy is turned into kinetic energy, ejected into suction (mixing) chamber and mixed with evacuated gas. Then the energy is exchanged. When mixed air entering the diffuser, its speed lowered and pressure increased, the kinetic energy is turned into pressure energy. Followed can be found the general working principle:

besides, it’s also good option to be worked together with liquid ring vacuum pump to create higher ultimate pressure.

The combination of ejector and condenser meets various needs of vacuum

Main Features:

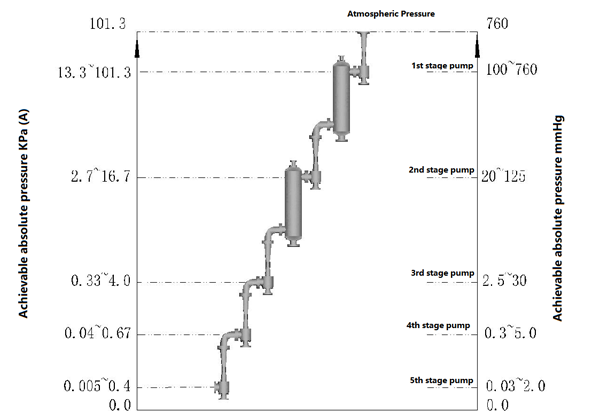

The working vacuum range is very wide: 0.005-101.3KPa (A);

The pumping volume can theoretically be unlimited;

There are no strict restrictions on the pumping medium, no matter the humidity of the pumped medium is high or low, whether there is dust or corrosion, it can be used;

No rotating parts, long service life;

Safe and reliable work, simple operation, low cost and easy maintenance;

With an intermediate condenser, a 12m high position is required;

Simple structure; reliable technology;stable vacuum degree; low maintenance and long service life.

It can be used to suction some corrosive gas, flammable, explosive gas and particulate medium,etc. directly.

Multi-stage steam ejector vacuum system with leading technology, stable performance and the lowest operating cost features. The other products are incomparable.

Steam jet vacuum pump features and applications:

vacuum metallurgy, vacuum deaeration, vacuum impregnation, freeze drying, concentration, distillation, refrigeration,vacuum evaporation of petroleum, chemical, pharmaceutical, oil, sugar, salt, paper and other fields,such as concentration, drying, distillation, distillation, crystallization, dehydrated, filtering, vacuum conveying material, chemical absorption and degassing process. With different pumping speed and working vacuum, we have many types of model for customer selection.

Specifications:

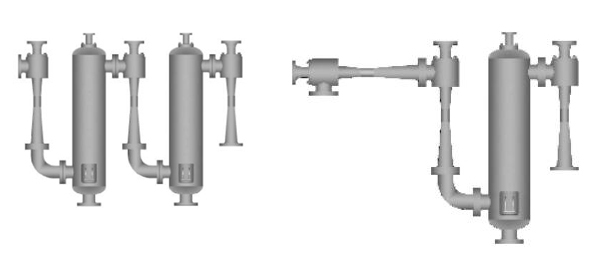

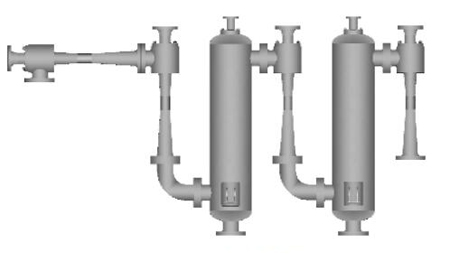

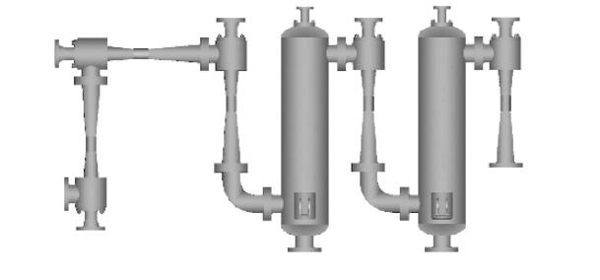

Steam jet vacuum pump layout :

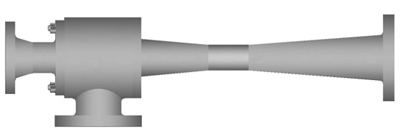

Single stage steam jet vacuum pump

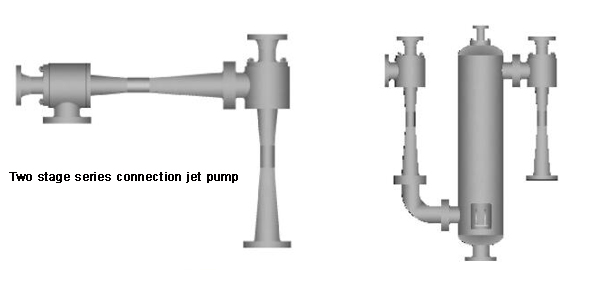

Two stage steam jet vacuum pump

| model | Vacuum absolute pressure |

Pumping volume

Air + water vapor kg/h |

Working steam pressure

MPa |

Working steam consumption

kg/h |

Cooling water temperature

OC |

Cooling water circulation

m3/h |

|

|

Working vacuum

mmhg/KPa |

Ultimate vacuum

mmhg/Pa |

||||||

| ¢òZPL(5/10)-40 | 40/5.3 | 16/2 | 5+10 | 0.5 | 68 | 32 | 3 |

| ¢òZPL(5/18)-40 | 40/5.3 | 16/2 | 5+18 | 0.5 | 110 | 32 | 4 |

| ¢òZPL(10/25)-40 | 40/5.3 | 16/2 | 10+25 | 0.5 | 188 | 32 | 6 |

| ¢òZPL(10/35)-40 | 40/5.3 | 16/2 | 10+35 | 0.5 | 198 | 32 | 7.5 |

| ¢òZPL(15/50)-40 | 40/5.3 | 16/2 | 15+50 | 0.5 | 273 | 32 | 11 |

| ¢òZPL(15/80)-40 | 40/5.3 | 16/2 | 15+80 | 0.5 | 420 | 32 | 16 |

| ¢òZPL(25/45)-75 | 75 | 30/4 | 25+45 | 0.8 | 135 | 32 | 6.8 |

| ¢òZPL(35/55)-75 | 75 | 30/4 | 35+55 | 0.8 | 238 | 32 | 7 |

Three stage steam jet vacuum pump

| model | Vacuum absolute pressure |

Pumping volume

Air + water vapor kg/h |

Working steam pressure

MPa |

Working steam consumption

kg/h |

Cooling water temperature

OC |

Cooling water circulation

m3/h |

|

|

Working vacuum

mmhg/KPa |

Ultimate vacuum

mmhg/Pa |

||||||

| ¢óZPL(8/20)-20 | 20/2.6 | 8/1 | 8+20 | 0.5 | 80 | 32 | 5 |

| ¢óZPL(8/30)-20 | 20/2.6 | 8/1 | 8+30 | 0.5 | 130 | 32 | 8 |

| ¢óZPL(10/40)-20 | 20/2.6 | 8/1 | 10+40 | 0.5 | 155 | 32 | 10 |

| ¢óZPL(10/50)-20 | 20/2.6 | 8/1 | 10+50 | 0.5 | 234 | 32 | 15 |

| ¢óZPL(10/60)-20 | 20/2.6 | 8/1 | 10+60 | 0.5 | 256 | 32 | 18 |

| ¢óZPL(10/80)-20 | 20/2.6 | 8/1 | 10+80 | 0.5 | 289 | 32 | 20 |

| ¢óZPL(10/100)-20 | 20/2.6 | 8/1 | 10+100 | 0.5 | 335 | 32 | 35 |

| ¢óZPL(20/150)-20 | 20/2.6 | 8/1 | 20+150 | 0.5 | 387 | 32 | 35 |

| ¢óZPL(20/200)-20 | 20/2.6 | 8/1 | 20+200 | 0.5 | 456 | 32 | 40 |

| ¢óZPL(30/250)-20 | 20/2.6 | 8/1 | 30+250 | 0.5 | 491 | 32 | 45 |

| ¢óZPL(30/300)-20 | 20/2.6 | 8/1 | 30+300 | 0.5 | 532 | 32 | 48 |

| ¢óZPL(30/350)-20 | 20/2.6 | 8/1 | 30+350 | 0.5 | 732 | 32 | 50 |

| ¢óZPL(40/400)-20 | 20/2.6 | 8/1 | 40+400 | 0.5 | 789 | 32 | 55 |

| ¢óZPL(40/450)-20 | 20/2.6 | 8/1 | 40+450 | 0.5 | 888 | 32 | 60 |

Four stage steam jet vacuum pump

| model | Vacuum absolute pressure |

Pumping volume

Air + water vapor kg/h |

Working steam pressure

MPa |

Working steam consumption

kg/h |

Cooling water temperature

OC |

Cooling water circulation

m3/h |

|

|

Working vacuum

mmhg/KPa |

Ultimate vacuum

mmhg/Pa |

||||||

| ¢ôZPL(8/20)-1 | 1/133 | 0.2/27 | 8+20 | 0.5 | 362 | 32 | 50 |

| ¢ôZPL(8/30)-1 | 1/133 | 0.2/27 | 8+30 | 0.5 | 430 | 32 | 50 |

| ¢ôZPL(10/40)-1 | 1/133 | 0.2/27 | 10+40 | 0.5 | 680 | 32 | 70 |

| ¢ôZPL(10/60)-1 | 1/133 | 0.2/27 | 10+60 | 0.5 | 980 | 32 | 100 |

| ¢ôZPL(10/80)-1 | 1/133 | 0.2/27 | 10+80 | 0.5 | 1230 | 32 | 160 |

| ¢ôZPL(10/100)-1 | 1/133 | 0.2/27 | 10+100 | 0.5 | 1500 | 32 | 180 |

| ¢ôZPL(20/120)-1 | 1/133 | 0.2/27 | 20+120 | 0.5 | 1980 | 32 | 200 |

| ¢ôZPL(20/150)-1 | 1/133 | 0.2/27 | 20+150 | 0.5 | 2500 | 32 | 200 |

| ¢ôZPL(20/200)-1 | 1/133 | 0.2/27 | 20+200 | 0.5 | 3000 | 32 | 250 |

| ¢ôZPL(30/300)-1 | 1/133 | 0.2/27 | 30+300 | 0.5 | 4500 | 32 | 300 |

| ¢ôZPL(40/400)-1 | 1/133 | 0.2/27 | 40+400 | 0.5 | 6000 | 32 | 380 |

| ¢ôZPL(50/500)-1 | 1/133 | 0.2/27 | 50+500 | 0.5 | 7000 | 32 | 550 |

| ¢ôZPL(80/800)-1 | 1/133 | 0.2/27 | 80+800 | 0.5 | 10000 | 32 | 650 |

| ¢ôZPL(8/20)-2 | 2/267 | 0.3/40 | 8+20 | 0.5 | 256 | 32 | 50 |

| ¢ôZPL(8/30)-2 | 2/267 | 0.3/40 | 8+30 | 0.5 | 295 | 32 | 50 |

| ¢ôZPL(10/40)-2 | 2/267 | 0.3/40 | 10+40 | 0.5 | 490 | 32 | 60 |

| ¢ôZPL(10/60)-2 | 2/267 | 0.3/40 | 10+60 | 0.5 | 680 | 32 | 70 |

| ¢ôZPL(10/80)-2 | 2/267 | 0.3/40 | 10+80 | 0.5 | 930 | 32 | 100 |

| ¢ôZPL(10/100)-2 | 2/267 | 0.3/40 | 10+100 | 0.5 | 1000 | 32 | 120 |

| ¢ôZPL(20/120)-2 | 2/267 | 0.3/40 | 20+120 | 0.5 | 1100 | 32 | 150 |

| ¢ôZPL(20/150)-2 | 2/267 | 0.3/40 | 20+150 | 0.5 | 1234 | 32 | 180 |

| ¢ôZPL(20/200)-2 | 2/267 | 0.3/40 | 20+200 | 0.5 | 1600 | 32 | 200 |

| ¢ôZPL(30/300)-2 | 2/267 | 0.3/40 | 30+300 | 0.5 | 2332 | 32 | 250 |

| ¢ôZPL(40/400)-2 | 2/267 | 0.3/40 | 40+400 | 0.5 | 2567 | 32 | 300 |

| ¢ôZPL(50/500)-2 | 2/267 | 0.3/40 | 50+500 | 0.5 | 3200 | 32 | 350 |

| ¢ôZPL(80/800)-2 | 2/267 | 0.3/40 | 80+800 | 0.5 | 3819 | 32 | 400 |

Five stage steam jet vacuum pump

Note:

1. The models listed in the table are not exhaustive, and can be designed according to the technical parameters provided by users.

2. The technical parameters change accordingly when the user’s process conditions change, so the technical parameters are subject to the technical parameters given at the time of signing the contract.