- Leak Detector

- Vacuum Products

- Claw Pump

- Diaphragm Pumps

- Diffusion Pumps

- Dry Rotary Vane Pumps

- Dry Screw Pump

- Dry Scroll Pumps

- Ion Pumps

- Laboratory Vacuum Pumps

- Liquid Ring Vacuum Pump & Compressor

- Piston Vacuum Pump

- Roots Pumping Systems RPS Series

- Rotary Vane Pumps

- Spare Parts & Accessories

- Turbo Pumping Systems

- Turbo Pumps

- Vacuum Components

- Vacuum Measurement

- Vacuum System

- Furnace

- Digital Oscilloscopes

- Yokogawa

- Rigol

- Rigol Digital Oscilloscopes DS80000 Series

- Rigol Digital Oscilloscope DS70000 Series

- Rigol Digital Oscilloscope MSO8000 Series

- Rigol Digital Oscilloscope MSO/DS7000 Series

- Rigol Digital Oscilloscope DS6000 Series

- Rigol Digital Oscilloscope MSO5000 Series

- Rigol Digital Oscilloscope MSO/DS4000 Series

- Rigol Digital Oscilloscope MSO/DS2000 Series

- Rigol Digital Oscilloscope DS1000 Series

- Rigol Digital Oscilloscope MHO/DHO5000 Series

- Rigol Digital Oscilloscope MHO2000 Series

- Rigol Digital Oscilloscope MSO8000A Series

- GW Instek

- Saluki

- Siglent

- Others

- Data Acquisition

- DC Electronic Load

- DC Power Supply

- Digital Multimeters

- LCR Meter

- Signal Generator

- Network Analyzer

- Spectrum Analyzers

- Waveform Generators

- Test & Measurement

- Flow Meter

- Manometer

- Optical Test

- Power Electronics Training Systems

- Safety Tester

- Other Meters

- Accessories for Test & Measurement

- Cable & Antenna Analyzer

- Cable & Pipe Locators

- Clamp Meter

- Comprehensive Tester

- GPS / GNSS Simulators

- Insulation Tester

- Non-Contact Voltage Tester

- Power Analyzer & Power Meter

- Power Supply

- Thermal Imager & Thermometer

- Transformer

- Professional Cleaning Equipment

- Professional Power Tools

- Angle grinders & metalworking

- Benchtop Tools & Benches

- Carrying Case

- Cordless Tools

- 12 Volt System

- 18 Volt System

- 18V Tools

- 36 Volt System

- Charger

- Cordless Angle Grinder

- Cordless Drywall Screwdrivers

- Cordless Dust Extractors

- Cordless hand-held circular saws

- Cordless impact drills

- Cordless Impact Drivers/Wrenchers

- Cordless Jigsaw

- Cordless Multi-Cutter

- Cordless Orbital Sander

- Cordless Palm Router

- Cordless Planer

- Cordless Reciprocating Saw

- Cordless Rotary Hammer

- Cordless Rotary Tool

- Cordless Straight Grinder

- Cordless Worklights

- Measuring Technology

- Diamond Technology

- Drills & impact drills & screwdrivers

- Dust Extraction Systems

- Heat Guns & Glue Guns

- High-Pressure Washer

- Measuring Technology

- Rotary Hammers & Demolition hammers

- Routers

- Sanders & Planers

- Saws

- Stirrers

- Rental

- MRO

- Jonnesway

- RS Pro

- Beacons

- Cabinet Coolers

- Cable Clips & Clamps

- Cage Nuts

- Camlocks

- Chisels

- Coaxial Cable

- Code Locks

- Compression Springs

- Counters

- Cutters

- DIN Rail Power Supplies

- Door Bolts

- Door Catches

- Door Closers

- Door Latches

- Door Stops

- Drawer Handles & Cabinet Handles

- Electronic Sounders

- Energy Meters

- Fixed Installation DC-AC Power Inverters

- Hammers

- Hasp & Staples

- HDMI Cables

- Heater Pads

- Heating Elements

- Hex Keys

- Impact Sockets

- Industrial Hubs & Switches

- Jack Cable Assemblies

- Multicore Microphone & Instrument Cable

- Number & Letter Punch Sets

- Nut Drivers

- Pliers

- Punches

- Rack Cable Management

- Rack Panels

- Rackmount Cases

- Screw Extractors

- Screwdriver Bit Sets

- Screwdriver Bits

- Screwdriver Sets

- Screwdrivers

- Scribers

- Sensor Accessories

- Server Cabinet Accessories

- Server Rack Shelves

- Single Core Microphone Cable

- Socket Accessories

- Socket Sets

- Socket Wrenches

- Spanner Sets

- Spring Plungers & Indexing Plungers

- Tap & Die Wrenches

- Temperature Control Accessories

- Temperature Controllers

- Temperature Probes

- Temperature Transmitters

- Thermocouple & Extension Wire

- Thermocouples

- Thermostatic Switches

- Time Switches

- Timer Relays

- Torque Screwdrivers

- Torque Wrenches

- Torx Keys

- USB Cables

- USB Extension Cables

- VGA Cables

- Others

- TEMO

- Skinny Tools

- Algodue

- Greenwipes

Hexo Industries (M) Sdn Bhd

1-2-9, i-Avenue, Medan Kampung Relau 1, 11900 Bayan Lepas, Penang, Malaysia.

+6011-6528 1088

+604-611 1186

+6012-954 1088

+604-611 1186

+6012-954 1088

+6012-558 2052

+60129541088

Selangor Branch

Jalan Putra Bistari 2/5J, 47610 Subang Jaya, Selangor, Malaysia

Indonesia Branch

Jababeka Bizpark, Blok D/16, Jababeka Innovation Center, Pintu 6, Blok D/16, Cikarang, Bekasi, Jawa Barat 60292, Indonesia.

Singapore Branch

SpectrumSense Solutions

1 Scotts Road, #24-10 Shaw Centre, Singapore 228208.

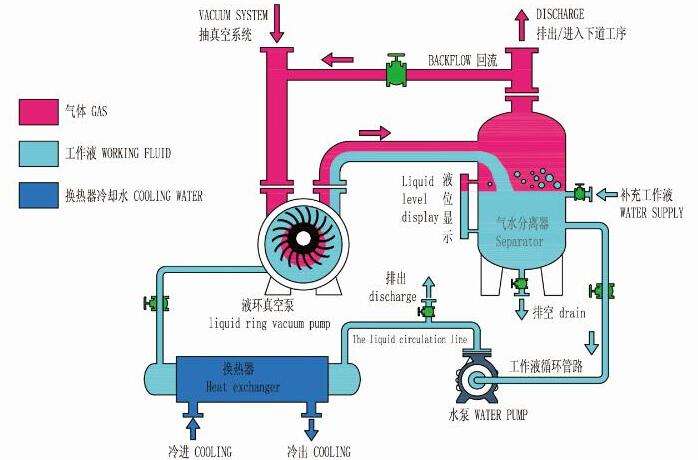

Closed Cycle Water Ring Vacuum System

| Previous | 4 / 20 | Next |

Closed Cycle Water Ring Vacuum System

Contact us at sales@hexoind.com to discuss your application need.Description: We provide a full range of water ring pump units such as 2BE series, 2BV series, 2SY Series, ZJZ series of all sets of units, including the steam separator, heat exchanger, connecting pipe, etc.

Product Info:

1. The normal operation of the water ring vacuum pump requires a lot of working fluid. Based on the different size of the pump, per hour of working fluid consumption is from 0.12m3 / h to 50m3 / h. If we only rely on continuous external water supply, then the consumption of water accumulated every year is very large. The application of the closed cycle vacuum system of the water ring pump can avoid the waste of working fluid.

2. In chemical industry, there are toxic and harmful liquid, and some flammable and explosive gas, the circulating fluid is not allowed to communicate with the outside world. So as to avoid pollution of the workplace, closed cycle vacuum system which adopts flow parts stainless steel & mechanical seal can solve such problems.

3. When under the situation that water quality can not be guaranteed, serious scale may be caused after running a very short period of time. And this can affect the normal operation of the pump. Then we can add a softening tank before the pump, composed of equipment similar to closed-loop unit to monitor the level with constantly adding soft water. By doing this can we guarantee the good operation of the system.

4. In order to make the system running smoothly and reliably, the pump group can be set to one open and one close (for preparation), or multiple open and multiple close (for preparation). When start the operation of the system, we open several pumps at the same time to meet the system process requirements within short time. Then after the return signal, electronically controlled or remote closed off the spare pump, leaving only one or several to maintain the pump to maintain the system vacuum, reducing the power of the entire system, shorten the process time and improve the automation.

5. Large equipment of water ring complete sets of vacuum pump systems can be used in gas drainage, pressure adsorption, transportation filtration and other industries. Our company designed a full set of mobile gas pumping pumping station, and equipped with a sound monitoring and control system, all supporting 2BE products to ensure the unit’s reliable operation.

6. When in the evacuation of closed containers, such as drying systems, the system required vacuum is much higher than the water ring pump, then we can connect Roots pump to become a Roots – water ring vacuum system to improve the suction capacity, ultimate vacuum to meet the requirements. The ultimate pressure of three Roots units plus water ring vacuum pumps can be about 0.5Pa.

7. High-pressure water ring compressor application must be added after a rear separator, the container is a pressure vessel category, playing the role of a gas-water separation, voltage transmission, and can provide circulating fluid. This kind of compressors can compress hydrogen, acetylene and other chlor-alkali industry generated gas. Generally with heat exchangers, centrifugal pumps and other accessories, all units only need to stay the interface, with user-friendly installation and commissioning.

-